QUALITY CRAFTSMANSHIPEach piece of wood is hand selected and inspected for quality control.

We understand that price can be a deciding factor for many homeowners when it comes to remodeling their kitchen, however they shouldn’t have to sacrifice quality. Being one of the largest investment and remodels that a home can go through, you want to make sure you are purchasing kitchen cabinets that are of high quality, and that will be able to withstand their daily use. Getting a good price and deal is only opportune if the product is made well. We go the extra mile when it comes to our kitchen cabinetry. First and foremost, we put our products through rigorous testing to ensure their quality craftsmanship. We know it seems like there are never ending choices of styles, colors, stains, etc. making purchasing the right kitchen cabinets stressful. You do not have to worry about selecting the wrong product because each piece of wood is hand selected and inspected before being assembled. No matter what the reason may be for your kitchen remodel, We ensure quality, and it is one thing they make sure homeowners do not have to worry about. You will see below the special features that come along with our kitchen cabinets:

|

SUPERIOR FINISH & QUALITY CONTROL1. We select only the finest wood species available. Each piece of lumber is hand selected to meet our quality standards prior to manufacturing [1] .

|

THE NATURAL BEAUTY OF SOLID WOOD

|

CABINET ANATOMY

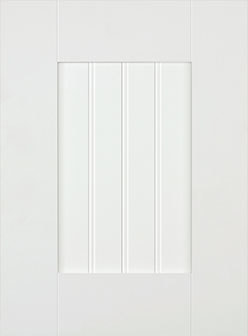

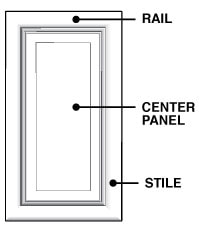

Your cabinetry will be constructed from several pieces of solid hardwood. Face frame, door and 5-piece drawer fronts consist of solid wood vertical members called stiles, and solid wood horizontal members called rails. The other component is the door and drawer front center panel.The center panel is made up of several individual solid hardwood pieces known as staves. These staves vary in width and are “glued up” to create large width panels that can be machined and profiled to create the desired look for the style of the cabinetry. The dotted lines on the photo below define the three (3) staves in door center panel.A typical door may contain seven (7) or more pieces of solid hardwood which gives your cabinetry a distinct and refined look. |

|

COLOR VARIATION

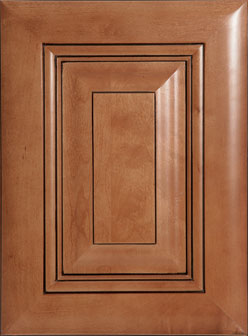

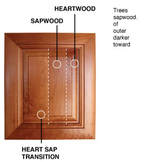

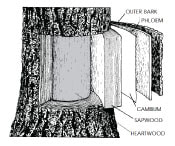

Trees consist of two (2) types of wood: heartwood and sapwood. Heartwood is old growth found in the core of the tree, and sapwood is newer growth found in the outer perimeter of the tree. Heartwood is typically darker and transitions to a lighter color as it moved toward the sapwood. Cabinetry component pieces are randomly selected from heartwood and sapwood to create a mix or blend of material to showcase the beauty of the wood and prevent the finished cabinetry from looking artificial or monochromatic. The door shown at the left is a beautiful example of the marriage of these hardwoods. |

|

GRAIN VARIATION

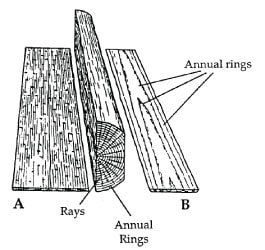

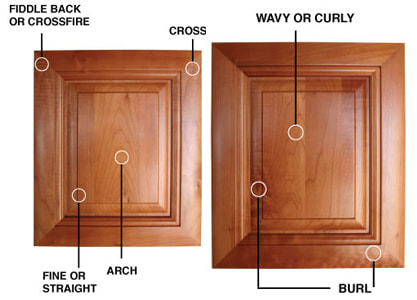

Grain in wood is caused by annual growth rings, wood rays, and other cellular structures contained within the wood. Grain runs vertical, or in the direction of height growth and is used to describe alignment and various patterns that may appear in your hardwood.The most common grain patterns are: fine or straight, cross, wavy or curly and arch. Injury to a tree can affect grain patterns creating very unique and exquisite patterns. Injury may be the result of stress, weather, birds or insects. The trees reaction is to produce a wart covering called burl to protect itself. It is from the burl that we see unusual grain patterns like fiddle back, tiger stripe and cross fire. Any or all of these patterns may be present in your cabinetry making it truly, one of a kind! |

|

OTHER CONSIDERATIONS

Your cabinetry may also have some species characteristics like closed knots (1), a blackish-blue streak called mineral streak (2), telegraphing (3), where some darkened grain shows through the stain or small brownish dots called birds eye (4).None of the characteristics pictured are to be considered flaws, blemishes or imperfections, but rather, examples of the beauties of Mother Nature. These are the same variations that will be found in granite, slate, marble or stone, which cannot be fully replicated with man made materials. It is for this reason that these characteristics cannot be considered for warranty replacement. Please remember that we do not make the wood, what we do is make the wood beautiful! |

THE ARTISTRY OF GLAZE AND PAINT FINISHES

|

STAIN/GLAZE

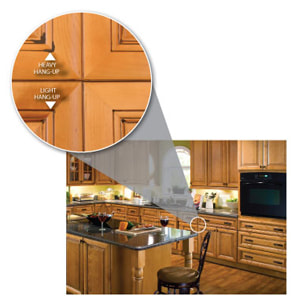

Glaze is a hand applied accent over a stain base coat designed to accentuate the detail of each door and drawer front and replicate the look of antique furniture. There will be a natural variation from door to door of glaze color highlights in the grooves of the door frame as well as “hang-up” in corners of the frame. Because of the hand applied nature and technique of this finish, no two doors will have the same level of glazing. It is therefore very important to look at your cabinetry as a whole rather than focusing on an individual door, as the mix or blend of all doors will present a balanced unique look. |

PAINT/GLAZE

Glaze accent applied over a painted base coat will be less “busy” as color variation from grain and base hardwood material is eliminated. The glaze application process is the same as with a stain base coat and you will find the same groove highlights and “hang-up” in corners as detailed above. |

|

Wood is in a constant state of expansion and contraction depending on your home’s relative humidity. This normal movement may cause some hairline cracks at the joints in the painted finish surface on doors, drawer fronts, and face frames. This is a natural occurrence and does not diminish or weaken the strength of the joints. These hairline cracks occur in all finishes, but are more visible in painted finishes. ALL INFORMATION ABOVE IS FROM THE MANUFACTURER'S WEBSITE / CATALOG |